Located on 50-acre campus minutes outside the rapidly growing Greenville, SC, MPF has been supplying feedthroughs and viewports to a myriad of Fortune 500 companies, cutting-edge research laboratories, and emerging tech start-ups for more than 20 years.

MPF is recognized by our customers, suppliers, and employees as the leading experts in ceramic-to-metal sealing technology. We are dedicated to supplying our customers with the absolute best products, value and service.

We opened our new facility with 8,000 square feet. We also launched a standard product line that offered UHV viewports, power feedthroughs, coaxial connectors and thermocouple connectors for numerous industries including Semiconductor, Vacuum Coating, Oil and Gas, Photonics, Nanotechnology, Green Energy and Mil/Aero.

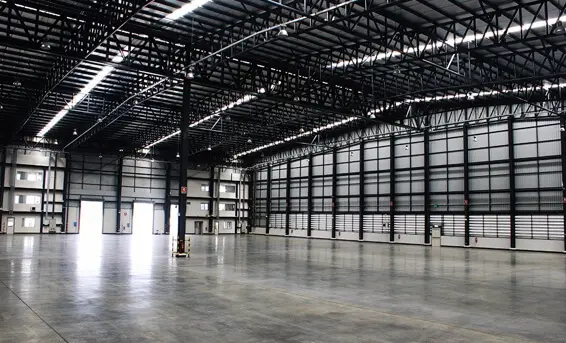

We increased our factory size to 12,000 square feet to accommodate the increasing demand for Electrical Feedthroughs, Viewports and Custom Ceramic-to-Metal assemblies. Additional furnaces, inspection equipment and employees were also added to bring more expertise and technology to MPF.

We have upgraded our design software, inspection equipment, leak test equipment, vacuum brazing capacity, and manufacturing software. MPF continues to invest in equipment and upgrades to our manufacturing tools as our diverse customer base introduces us into new marketplaces with challenging design requirements. We launched a new user-friendly website to help customers navigate over 2,200 standard part numbers and numerous resources. We now have a network of International Partners spanning Europe & Asia, along with highly experienced sales representatives strategically located throughout the United States.

MPF Products was purchased in 2020 by a group of dedicated long-term investors – Fulham & Co. MPF was immediately provided with larger sources of capital investments to pursue add-on businesses, capital equipment and additional personnel.

We have recently received the coveted ISO 9001:2015 certification for quality management systems. For MPF, this designation confirms that the design, testing protocols, and inspection of the thousands of vacuum vessel components we deliver to our partners in the scientific community, adheres to the quality and performance standards of much larger companies.

MPF Products purchased Blue Ridge Optics located in Bedford, VA. Blue Ridge Optics is a fully integrated manufacturer of Thin Film Coatings and Precision Optics used in advanced high energy laser systems. They are also a leader in the development and production of high-energy laser optics for aerospace, medical, OEM, science, and laboratory applications. The combination of the companies will lead to more comprehensive R&D to develop the latest technologies in the fabrication and coating of precision optics to serve our clients. Please see more of our capabilities by visiting Precision Optics by Blue Ridge Optics

– Captain Jean-Luc Picard

Star Trek

Subscribe to learn more about the impossible science at MPF.

MPF Products, INC.

3046 Bramlett Church Rd.

Gray Court, SC 29645

Need Help?

No problem. Call us at (864) 876-9853 or email us at [email protected].